Latest news

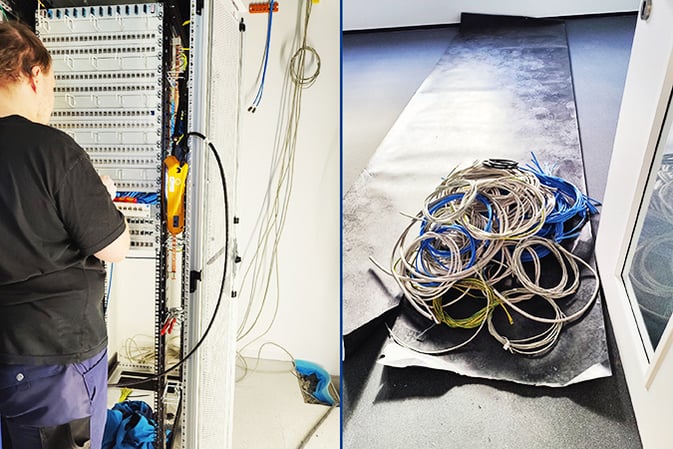

We're excited to bring you the latest images from our new building! As you can see the scaffolding is finally down and the new facility looks beautiful in early spring sunshine. Things are really taking shape inside as well now, and we have many exciting developments to share. The facility is an essential part of our strategy to drive down lead-times and meet the long-term growth in sample support requirements in the cryo-electron microscopy community, and we're really pleased with the rapid progress towards the realisation of our plans. Take a look below to see the labs and offices really starting to take shape.